Imagine opening your medicine cabinet—how many of your pills or bottles were made in the same country you live in? Probably fewer than you think. If you've ever wondered where most of the world’s pharmaceuticals are actually produced, you’re not alone. People tend to guess Switzerland (because of all those tiny white pills), India (the ‘pharmacy of the world’), or sometimes the US (the home of Big Pharma). But what if I told you that picking just one winner is much more dramatic than a simple trivia answer? There’s a lot at stake here: billions of dollars, massive labs, armies of scientists, and—the most important bit—your health and mine.

The Power Players: Who Actually Leads Pharmaceutical Production?

Let’s clear up the confusion first. If you go by sheer dollar value—basically, the total revenue from pharmaceuticals—the United States stands alone at the top of the global pile. In 2024, American pharmaceutical companies generated about $610 billion in pharmaceutical sales. That’s more than double Switzerland, which came in at $243 billion, and far ahead of Germany, at nearly $65 billion. There’s a reason people talk about “Big Pharma” when referring to American industry giants like Pfizer, Johnson & Johnson, and Merck. These aren’t just buzzwords. It’s pure dose-by-dose dominance. The US is not just tossing out lots of pills; it’s creating the world’s best-selling and most expensive drugs.

But there’s a twist: If you look at where the actual pill production—the mixing, pressing, and packaging of tablets—happens, the winners shift. India and China play a massive role here. India, for example, is now called “the pharmacy of the world” for good reason: Over 20% of generic (off-patent) medicines used around the globe are made there. Indian factories shipped pharmaceuticals to over 200 countries in 2024. China, on the other hand, is the unspoken force behind most active pharmaceutical ingredients (APIs)—basically the chemical guts of your medicine. It supplies something like 40% of the world’s heaviest-hitting pharmaceutical ingredients.

So, who’s the largest producer of pharmaceuticals? It depends on what you’re measuring. US for cash value and R&D, India for sheer volume and reach, China for those core ingredients. The actual winner? Maybe it’s a strange three-way tie, unless you're asking about a specific metric—and then results change fast.

| Country | Pharmaceutical Market Size (USD Billion, 2024) | Key Strength |

|---|---|---|

| United States | 610 | R&D, Innovation, Revenue |

| Switzerland | 243 | Global Brands, High-Value Exports |

| Germany | 65 | Engineering, Medical Tech |

| India | 53 | Generic Drug Production, Volume |

| China | 50 | APIs, Chemical Ingredients |

So next time you reach for a painkiller, chances are the science was developed in the US or Europe, the core ingredient came from China, and it was pressed into a pill in India or somewhere nearby. That’s what “globalization” really means in medicine.

Why the US Still Sets the Tone for Global Pharma

Everybody likes to call out the dominance of Indian factories or talk about how many basic drugs China pumps out, but when it comes to setting the trends—and making the drugs that rake in the real money—the US is still way out front. The reason is pretty simple: American companies pour astonishing sums into research every year. We’re talking more than $110 billion in pharmaceutical R&D spending in 2024 alone. Some drugs take a decade or more to develop. Anticancer medicines, specialty treatments for rare diseases, personalized gene therapy—the blockbuster drugs shaping medicine’s future are nearly always born in US laboratories.

Pharmaceutical giants based in the US, like Pfizer (think COVID-19 vaccines), Merck (the first real breakthrough in HIV/AIDS), and Johnson & Johnson (just about everything else), have more at stake in R&D than in simply churning out bottles of aspirin. They license formulas, run clinical trials on every continent, and then outsource or partner with companies in India or China for high-volume manufacturing. The cycle typically looks like this: innovator company in the US, patent protection for 20 years, initial high prices for the newest drugs, and, when patents expire, lower-cost production in India, China, or Brazil.

There’s another hidden advantage to the American system: access to funding and the fastest approval pipeline for breakthrough drugs. The Food and Drug Administration (FDA) greenlights new medicines faster than most regulatory agencies worldwide. That’s why, even if you live in Germany or Singapore, your fancy new cancer immunotherapy probably had its big break in New York or Boston before showing up on your hospital shelf.

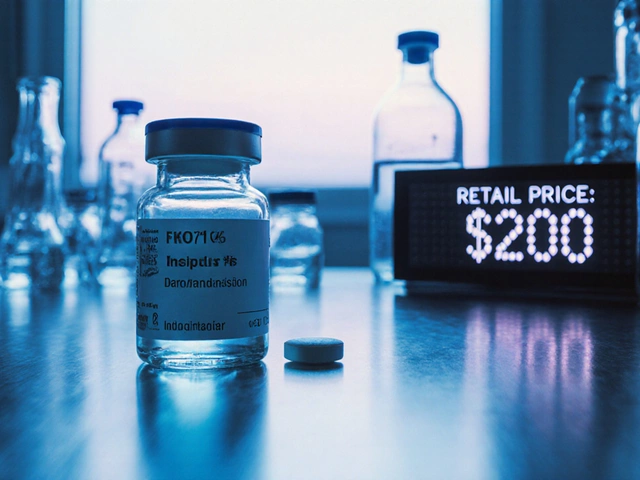

And yet, this leadership comes with a price. The US also pays more for its medicines than any other country—sometimes 3 to 4 times more than Europeans or Asians pay for the same pills. Talk about irony, right? The same companies setting the pace in science also drive debates at your neighborhood pharmacy about ridiculous copays and insurance headaches.

India & China: Factories of the World’s Medicines

The “largest producer” isn’t always the flashiest—it’s about volume, and that’s where India and China become the heroes and villains of global pharma narratives. A whopping 60% of global vaccine supply comes from Indian companies. If there’s a basic blood pressure medicine, antibiotic, or pain reliever in your drawer, odds are decent it was made or bottled somewhere on the Indian subcontinent. Even the World Health Organization counts on Indian-made vaccines for its biggest programs targeting malaria, polio, and measles in Africa and beyond.

Indian giants like Sun Pharma, Cipla, and Dr. Reddy’s Laboratory have turned generic drug production into a science. The secret sauce? Scale and cost control. Factories in Hyderabad or Mumbai can crank out millions of tablets daily for a fraction of what it would cost in Europe or the US. It’s not just about cheap labor—the government has nurtured the industry, and the science behind generic drugs is world-class. That’s why you see “Made in India” labels on everything from anti-HIV cocktails shipped to Southeast Asia to aspirin sold in Europe.

But India could not pull off this massive operation without China quietly dominating the raw material supply. If you dig into any packet of blood thinner or a heart medicine, you’ll find most “active pharmaceutical ingredients” (APIs) started life in Chinese factories in cities like Shanghai or Tianjin. API production is gritty work—chemistry on a bulk scale with tons of regulation headaches and environmental scrutiny. It’s not glamorous, but it’s absolutely essential. Some years, China exports nearly $30 billion worth of these ingredients.

This tangled supply chain means a hiccup in one country can mess up medicine supplies everywhere else. Remember early 2020? US hospitals scrambled as Chinese factories paused operations due to COVID-19, showing exactly how intertwined everything has become. If Rohan and I ever have a minor family crisis at midnight—the ones where you wind up frantically searching for antibiotics or fever meds—you can bet at least two countries were involved in making whatever ends up in your hand.

The Risks, Realities, and the Road Ahead: What the Future Looks Like

With so much of the world’s pill-popping power split across continents, there’s always a risk of disruption. If a factory in India runs into regulatory trouble—or if geopolitical tensions heat up between the US and China—entire medicine supplies can vanish almost overnight. That’s not paranoia. In 2024, a quality-control shutdown at just one Indian plant left US pharmacies low on a major diabetes drug for nearly three months. American and European governments have started to ask, maybe a bit anxiously: Should we bring more manufacturing back home? But setting up a new chemical plant costs hundreds of millions, takes years, and comes with lots of red tape (not to mention environmental battles from nearby residents).

Yet there’s hope in how global this industry has become. The pandemic exposed the weaknesses, sure, but it also showed how quickly scientists and manufacturers could work when everyone’s back was pushed to the wall. Think about the speed of mRNA vaccine rollout by Pfizer in the US, or the scale-up of vaccine manufacturing by Serum Institute of India (now the world’s largest maker of vaccines by volume).

If you want a tip for the future, keep an eye on countries like Brazil, Turkey, or South Korea. They’re rapidly scaling up local manufacturing, trying to carve slices out of the big players’ market share. And with new technology—robotic factories, AI-driven drug development—there’s no reason to think the leaderboards can’t shift in another decade.

Until then, the answer to who is the largest producer of pharmaceuticals is a bit like opening a Russian doll: the US leads for value and science, China for raw materials, and India for actual pills. Every cough syrup and allergy tablet could have taken a detour through three or four countries before making its way into your shopping bag. You might never look at your medicine cabinet the same way again.

![Which Country Dominates Global Pharmaceutical Production? [Data-Driven Guide 2025]](/uploads/2025/07/which-country-dominates-global-pharmaceutical-production-data-driven-guide.webp)