Barter Value Calculator for Manufacturing Startups

Calculate Your Barter Potential

Find what materials or services you could get by bartering your manufacturing skills. This calculator helps you determine the potential value of exchange based on local market rates.

Starting a manufacturing business without money sounds impossible-until you see people in Bangalore, Jaipur, and Coimbatore doing it with nothing but skills, sweat, and smart swaps. You don’t need a factory, a loan, or investors to begin. You need a problem to solve, a skill you already have, and the guts to start small. The truth? Most successful manufacturers didn’t start with capital. They started with a prototype, a local market, and a willingness to trade work for resources.

Start with what you already own

You don’t need to buy machines to make things. Look around your home or workshop. Do you have a sewing machine? A drill? A soldering iron? A wood lathe? These aren’t just tools-they’re production lines waiting to be activated. In Bangalore, a woman turned her old sewing machine into a ₹50,000/month business making custom cushion covers for local hotels. She didn’t buy fabric-she collected discarded upholstery from repair shops. She didn’t hire workers-she trained her sister. Her entire startup cost: ₹0.

Identify one item you can make using tools you already have. It could be metal brackets, hand-painted pottery, woven bags, or simple electronic enclosures. Focus on something that solves a daily problem: a phone stand that doesn’t slip, a reusable spice container that fits your kitchen shelf, or a durable carry bag for auto-rickshaw drivers. Make it useful. Make it simple. Make it repeatable.

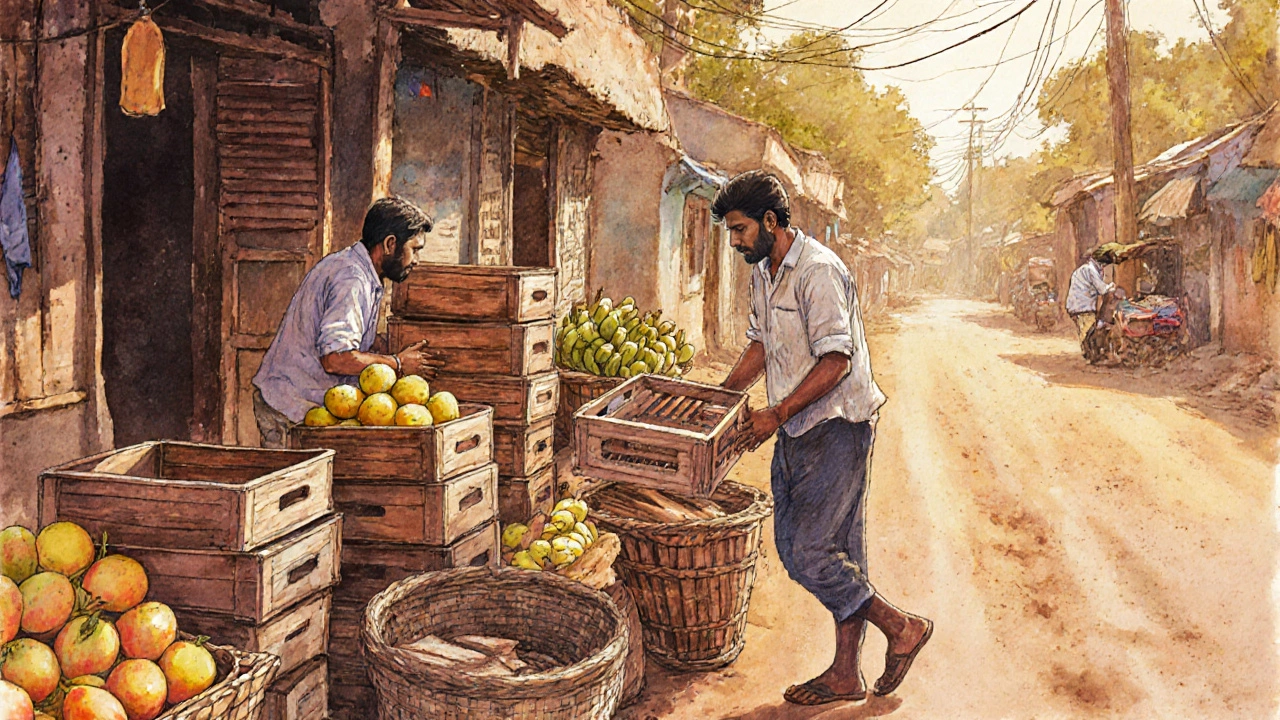

Barter, don’t buy

Money isn’t the only currency. Time, skills, and connections are just as valuable. In rural Tamil Nadu, a man built wooden crates for fruit vendors by trading his carpentry work for raw timber. He asked local orchard owners: “I’ll make your crates for free-if you give me the scrap wood after you unload your produce.” They said yes. Within three months, he had 30 clients and a pile of free wood. He didn’t pay a rupee for materials.

Find people who need what you can do-and offer to make something for them in exchange for materials, space, or help. A metalworker in Hyderabad swapped welding services for access to a garage. A potter in Mysore traded handmade bowls for clay from a nearby kiln owner. You’re not begging for handouts. You’re creating value exchanges. This is how bootstrapped manufacturing thrives.

Use government schemes-no loan needed

India has dozens of programs designed for small manufacturers who start with nothing. The Prime Minister’s Employment Generation Programme (PMEGP) gives up to ₹25 lakh in subsidy for micro-enterprises. You don’t need money upfront-you need a business plan and a bank account. The UDYAM Registration is free, takes 15 minutes, and unlocks access to subsidies, tax breaks, and raw material discounts.

Visit your nearest District Industries Centre (DIC). Ask for the list of approved schemes for your product category. In many states, you can get free training, toolkits, and even a small workspace for 6-12 months. One woman in Lucknow started making herbal soaps using free training from a DIC. She got free packaging materials, and her first 100 units were sold through a government-run khadi store. Her startup cost: ₹0.

Make it local, sell it local

Forget Amazon or Flipkart. Start where people already gather. A street vendor in Delhi sells handmade steel tumblers made from recycled kitchen pots. He doesn’t advertise. He doesn’t have a website. He just sets up his table near the bus depot every morning. His customers? Auto drivers, tea stall owners, and local shops. He makes ₹800 a day. Profit margin? 70%.

Your first customers aren’t online. They’re your neighbors, your aunt’s tailoring shop, the local gym owner, the school canteen. Walk around. Ask: “Do you need something made that you can’t find?” You’ll be surprised how many people are tired of buying cheap, broken stuff. Offer to fix it, remake it, or improve it. Charge in cash. Reinvest every rupee into better tools or materials.

Start with one product. One customer. One batch.

Don’t try to build a catalog. Don’t design 10 products. Pick one. Make five. Sell them. Repeat. In Pune, a man started by making simple wooden bookends from discarded plywood. He sold them to local students for ₹50 each. He made 30 in a week. He used the ₹1,500 to buy a better saw. Next week, he made 50. In three months, he had a small workshop, two helpers, and a waiting list.

That’s the pattern: make → sell → reinvest → repeat. Every rupee you earn is fuel. Every satisfied customer is your marketing team. You don’t need funding-you need momentum. The more you make, the more you learn. The more you learn, the better you get. And better means you can charge more.

Use free digital tools to scale

You don’t need a website. But you do need visibility. Use WhatsApp. Make a simple photo album of your products. Send it to 10 people you know. Ask them to share it with one other person. In 48 hours, you’ll have 100 views. Use Canva (free version) to make posters. Post them on local Facebook groups: “Handmade wooden spoons from recycled teak-₹40 each. Pickup only in Jayanagar.”

Use Google Sheets to track orders. Use free inventory apps like Inventory Now or Sortly (free tier). You don’t need ERP software. You need consistency. Track what sells. Track what breaks. Track who pays on time. That’s your business intelligence.

Reinvest everything

Here’s the rule: never spend your first ₹10,000 on anything that doesn’t directly help you make or sell more. No fancy packaging. No branded shirts. No Instagram ads. Buy a second-hand clamp. Pay someone to fix your drill. Rent a small shed for ₹2,000/month. Upgrade your saw. That’s it.

When you hit ₹20,000 in monthly sales, buy a second machine. When you hit ₹50,000, hire one part-time helper. When you hit ₹1 lakh, register your brand. Every step is funded by your own sales. No debt. No investors. No waiting.

Real example: From ₹0 to ₹1.2 lakh/month

In Hosur, a woman named Priya started making reusable cloth napkins from old sarees. She had no money. She had a sewing machine, 10 old sarees from her mother-in-law, and a WhatsApp group of 27 women from her colony. She made 20 napkins. Charged ₹20 each. Sold them all in two days. Used the ₹400 to buy 5 more sarees. Made 50. Sold them at the local temple fair. Next week, she added matching placemats. Then, she started taking custom orders for wedding sets.

By month three, she was working 10 hours a day. She hired two neighbors to help. She registered as a micro-unit under PMEGP. Got a ₹50,000 subsidy for a second machine. Today, she sells to 12 restaurants and 3 boutique hotels. Monthly revenue: ₹1.2 lakh. Startup cost: ₹0.

What not to do

Don’t wait for perfect conditions. Don’t ask for permission. Don’t buy equipment you don’t need yet. Don’t try to compete with big brands. Don’t chase trends. Don’t spend money on logos before you’ve sold your first product.

Don’t think you need to be an engineer, an MBA, or a tech wizard. You just need to be someone who sees a problem and says, “I can fix that.”

Next steps

Today, right now, do this:

- Write down one thing you can make using tools you already have.

- Find three people nearby who might need it.

- Make five units.

- Sell them for cash.

- Reinvest the money into one better tool.

That’s your manufacturing business. No loan. No investors. No excuses.

Can I start a manufacturing business with no money in India?

Yes. Thousands of small manufacturers in India start with zero cash. They use free government schemes, barter for materials, make products from scrap, and sell locally. The key is starting small, reinvesting every rupee, and focusing on one product until it sells. You don’t need money-you need action.

What are the best low-cost manufacturing ideas for beginners?

The best ideas use materials you can get for free or cheap: cloth napkins from old sarees, wooden utensils from scrap wood, metal hooks from discarded pipes, herbal soaps from kitchen oils, or phone stands from recycled plastic. Choose something simple, local, and useful. Avoid electronics or complex machinery until you have cash flow.

How do I get raw materials without paying?

Ask local shops, repair centers, or waste collectors for scrap. Tailors give fabric offcuts. Auto workshops give metal shavings. Fruit vendors give wooden crates. Bakeries give used flour sacks. Offer to clean their space or help with small repairs in exchange. Most people are happy to give away waste if it means less hassle for them.

Do I need a license to start small-scale manufacturing?

For very small operations (under ₹1 crore turnover), you don’t need a manufacturing license. But you must register under UDYAM-it’s free and takes 15 minutes online. It gives you access to subsidies, bank loans later, and legal protection. Don’t wait until you’re big. Register now.

How long does it take to make money from a zero-investment manufacturing business?

If you follow the make-sell-reinvest cycle, you can make your first ₹500-₹1,000 in 3-5 days. Break even on your first tool within 2-4 weeks. Most people reach ₹20,000-₹50,000 monthly within 3-6 months. Speed depends on how fast you sell and reinvest. Don’t delay. Start today.

If you’ve read this far, you already have what it takes. You don’t need money. You need to start.