Imagine turning $100,000 into a cash‑flowing factory in less than two years. With the right niche, even a modest budget can launch a business that delivers steady profits and room to grow. Below you’ll find the top manufacturing ideas that squeeze the most profit out of a six‑figure investment, a quick way to compare them, and the exact steps to get your operation off the ground.

How to pick the most profitable niche

First, focus on three key signals:

- Margin potential: products with raw‑material costs below 30% of the selling price usually leave room for healthy gross margins.

- Market demand: Look for items that serve an everyday need or a fast‑growing trend.

- Scalability: Choose a process that can be expanded without huge new capital outlays.

When these three line up, the return on investment often crosses the 30‑40% mark within the first 12‑18 months.

Top five high‑profit small‑scale ideas under $100K

Each of the following businesses meets the margin, demand, and scalability criteria. The first mention of every idea includes a micro‑data block so search engines can recognize the core concepts.

PVC Pipe Manufacturing is a low‑cost, high‑volume process that serves construction, irrigation, and plumbing markets worldwide. Raw material (PVC resin) prices have stayed under $1 kg, while finished pipes sell for $2‑$5 per kilogram, delivering gross margins around 50%.

Herbal Soap Production taps the growing clean‑beauty trend. Using locally sourced oils and herbal extracts keeps ingredient costs at 20‑25% of the retail price, and eco‑conscious consumers are willing to pay a premium.

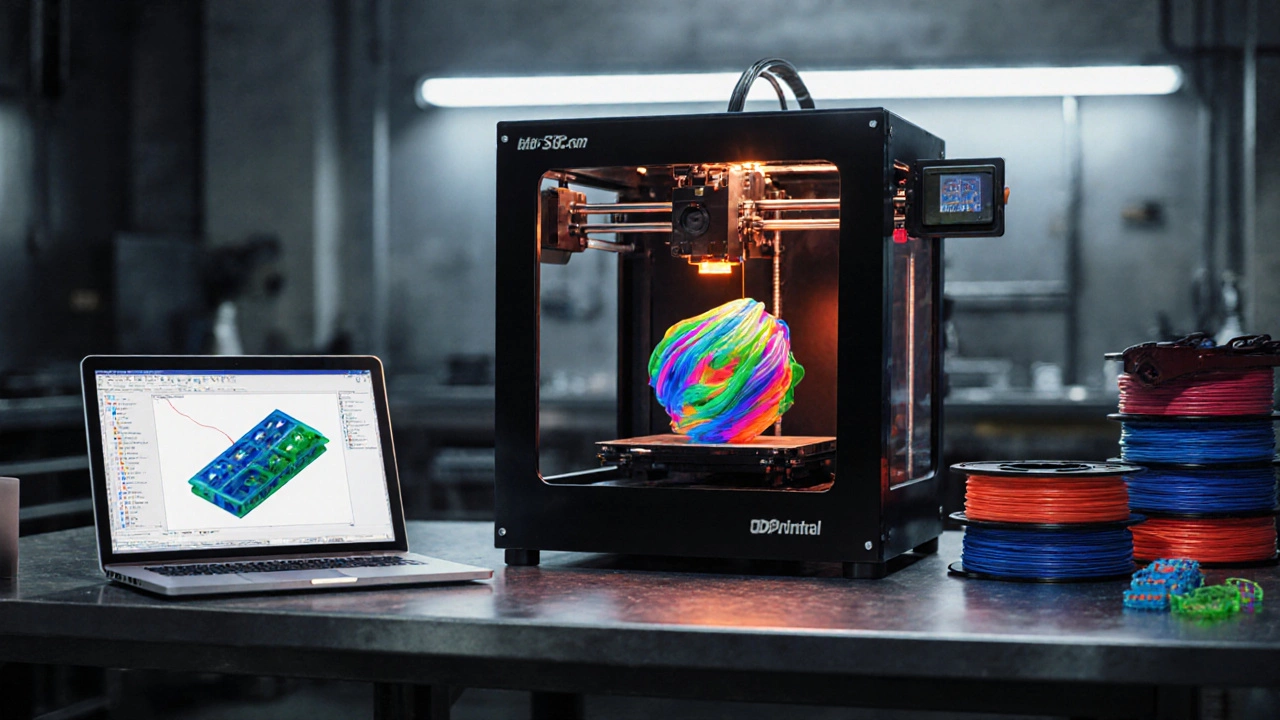

3D Printing Service converts digital designs into plastic, metal, or resin parts on demand. With a single mid‑range printer costing $8,000‑$12,000, you can charge $30‑$150 per printed piece, achieving margins of 40%‑60% once the printer is amortized.

Solar Lantern Assembly meets the energy‑access gap in rural Asia and Africa. Simple LED lanterns with rechargeable batteries cost $5‑$7 to assemble, while retail prices hover around $15‑$20.

Food Processing Unit (e.g., packaged snacks, ready‑to‑eat meals) leverages existing raw material supply chains. With a modest 10‑tonne per month capacity, profit margins can climb to 35%‑45%.

Side‑by‑side comparison

| Business | Initial Investment (USD) | Typical Gross Margin | Payback Period | Market Demand (2024‑2025) | Key Skill Requirement |

|---|---|---|---|---|---|

| PVC Pipe Manufacturing | $80,000 | ~50% | 12‑15 months | High (infrastructure projects) | Basic extrusion operation |

| Herbal Soap Production | $45,000 | ~45% | 9‑12 months | Growing (clean‑beauty) | Formulation & packaging |

| 3D Printing Service | $30,000 | ~55% | 6‑9 months | Rising (prototyping, hobbyists) | CAD design basics |

| Solar Lantern Assembly | $50,000 | ~48% | 9‑14 months | Strong (off‑grid energy) | Soldering & QA |

| Food Processing Unit | $95,000 | ~40% | 14‑18 months | Robust (snack demand) | Hygiene & batch mgmt. |

Funding the venture: where does the 0K go?

Break the budget into three buckets:

- Equipment: 40‑55% - machines, tools, and a modest production line.

- Working capital: 25‑35% - raw material inventory, initial labor, and utilities for the first 3‑4 months.

- Compliance & marketing: 10‑15% - licensing, quality certifications, and a launch campaign.

Because many Indian states offer MSME subsidies, you can often shave 10‑20% off the equipment cost. Check the Make in India Scheme and the MSME loan programs for low‑interest financing.

Step‑by‑step launch checklist

- Validate demand: run a small pilot or pre‑order campaign on platforms like Amazon or local B2B portals.

- Secure a compliant facility: 500‑1,000 sq ft for most ideas; ensure zoning permits and fire safety clearances.

- Purchase core equipment: prioritize machines with warranty and local service contracts.

- Set up a simple ERP or spreadsheet for Break-even Analysis - track fixed vs variable costs.

- Hire skilled labor: 2‑3 operators, a quality inspector, and a sales lead.

- Apply for government schemes: upload the project proposal to the Bank Loan for MSME portal and claim capital subsidy.

- Launch a targeted marketing push: demo videos, social media ads, and local distributor outreach.

- Monitor Profit Margin weekly - adjust pricing or sourcing if it dips below 30%.

Potential pitfalls and how to avoid them

Even the most promising ideas can stumble if you ignore a few red flags.

- Underestimating working capital: keep a 20% buffer for raw‑material price spikes.

- Skipping quality certifications: many buyers in construction and food demand ISO or FSSAI approval; get them early.

- Neglecting after‑sales service: a simple warranty line can lock in repeat orders, especially for electronics or solar products.

- Choosing the wrong location: proximity to suppliers reduces logistics cost; for PVC and food, being near a port or highway is a win.

What’s the quickest path to profit?

If cash flow is your top priority, the 3D printing service often delivers the fastest break‑even because equipment cost is low and you can start with on‑demand orders. For a more stable, contract‑driven income, PVC Pipe Manufacturing shines - long‑term supply contracts with construction firms guarantee steady revenue.

Quick recap

- Three ideas stand out for highest margins: PVC pipe, 3D printing, solar lanterns.

- Keep initial spend under $100K by leveraging government subsidies and modest equipment.

- Validate demand before full‑scale rollout to avoid excess inventory.

- Track break‑even monthly; aim for a payback within 12‑15 months.

Can I start a manufacturing business with $100,000 in a Tier‑2 city?

Yes. Tier‑2 locations often have lower land and labor costs, making it easier to keep the total spend under $100K. The key is to pick a niche that doesn’t need heavy automation - like the five ideas listed above.

What government schemes can reduce my startup cost?

The Make in India Scheme offers capital subsidies up to 30% for eligible equipment. Additionally, the MSME credit guarantee fund provides low‑interest loans and sometimes a partial interest subsidy.

How long does it take to get ISO certification for a small factory?

For a basic ISO 9001 quality system, the audit process usually lasts 4‑6 weeks after you have documented procedures in place. Hiring a consultant can shave a few weeks off the timeline.

Is a 12‑month payback realistic?

If you stick to the cost breakdown, secure enough early orders, and keep operating expenses tight, a 12‑to‑15‑month payback is achievable for most of the ideas listed, especially PVC pipe and 3D printing.

What are the biggest risks for a food processing unit?

Regulatory compliance is the biggest hurdle - you’ll need FSSAI licensing, hygiene audits, and label approvals. Additionally, perishable inventory can become waste if demand forecasts are off.