India cotton: What it means for manufacturing, jobs, and local industry

When we talk about India cotton, the raw fiber grown across millions of acres in states like Gujarat, Maharashtra, and Telangana that feeds India’s textile and apparel sector. Also known as Indian cotton, it’s not just a farm product—it’s the foundation of one of the world’s largest textile industries. Every meter of cloth, every shirt, every pair of jeans made in India starts with this fiber. And while global brands talk about sustainability and fast fashion, the real story is happening here—where small mills, family-run spinning units, and rural laborers depend on cotton to make a living.

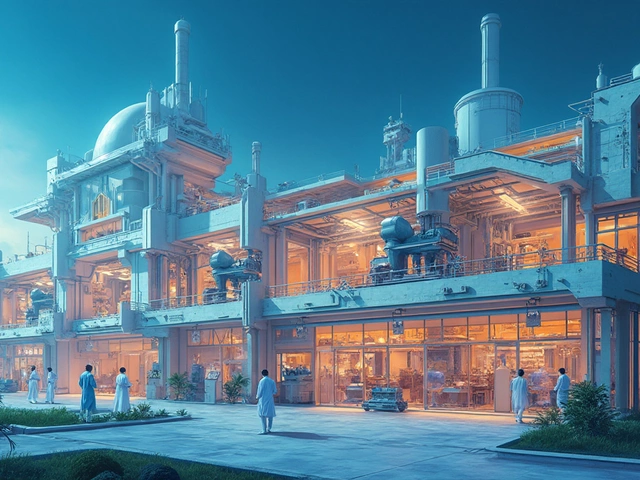

India cotton doesn’t just stay in the fields. It moves into factories that produce yarn, fabric, and finished garments. These aren’t just big plants—most are small-scale units, often run by families, that rely on government schemes like MOM to stay afloat. The same mills that make fabric for local markets also export to the US, Europe, and the Middle East. And when cotton prices swing, it ripples through everything: from the farmer’s income to the cost of a T-shirt in a Delhi market. It’s not just agriculture or manufacturing—it’s both, tied together by a single thread.

What’s often missed is how cotton connects to other industries. The cottonseed left after ginning becomes oil and animal feed. The stalks go into biofuel. Even the dust from spinning mills gets reused in insulation and packaging. And when global supply chains shift—like when the US stops buying or China raises tariffs—India’s cotton sector adapts. That’s why manufacturing businesses that use cotton, like textile processing or home goods production, often survive recessions better than others. People still need clothes, towels, and bedsheets, no matter the economy.

There’s also a quiet revolution happening. Farmers are switching to hybrid seeds that use less water. Factories are installing solar-powered looms. The government is pushing for better traceability so buyers know their cotton isn’t tied to unfair labor. All of this matters because India cotton isn’t just a commodity—it’s a system. And that system supports more than 60 million people directly, from seed to shelf.

Below, you’ll find real stories and data about how cotton shapes small factories, drives manufacturing startups, and links to larger trends in Indian industry—from chemical inputs for dyeing to export rules that affect who buys what. Whether you’re a farmer, a mill owner, or just curious about where your clothes come from, these posts break down the facts without the fluff.