U.S. Steel Plant Comparison Tool

U.S. Steel operates some of the largest and most historic steel production facilities in North America. If you’re wondering where these plants are, the answer isn’t just a list of cities-it’s a story of industrial legacy, regional resources, and modern logistics. Today, U.S. Steel runs active mills across seven states, each chosen for access to iron ore, coal, water, rail, and markets. These aren’t just factories; they’re the backbone of American infrastructure, supplying steel for bridges, cars, appliances, and pipelines.

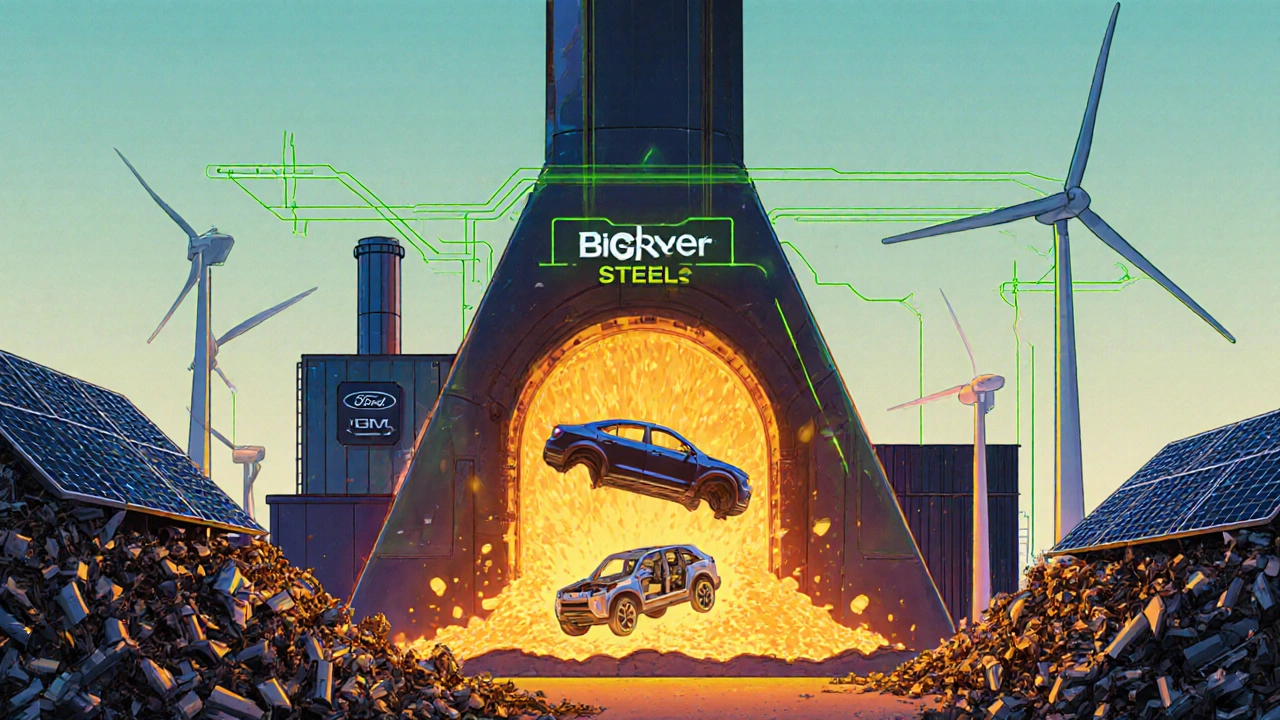

Big River Steel in Arkansas

One of U.S. Steel’s newest and most advanced mills is Big River Steel in Osceola, Arkansas. Opened in 2018, this facility uses electric arc furnace technology to recycle scrap steel into high-quality flat products. Unlike traditional blast furnaces, it doesn’t rely on coal or iron ore pellets. Instead, it runs on electricity and recycled metal, making it one of the most efficient and environmentally friendly steel plants in the country. Big River Steel produces over 2 million tons of steel annually and supplies auto manufacturers like Ford and General Motors with high-strength steel for vehicle frames and body panels.

Gary Works in Indiana

The Gary Works, located in Gary, Indiana, is U.S. Steel’s largest integrated steel mill and one of the biggest in the Western Hemisphere. Built in 1906, it’s been producing steel for more than a century. The mill sits right on the southern shore of Lake Michigan, giving it direct access to iron ore shipped from Minnesota via the Great Lakes. Coal comes in by rail from Pennsylvania and West Virginia. Gary Works has six blast furnaces, multiple coke ovens, and continuous casting lines. It produces over 7 million tons of steel each year-mostly for automotive, construction, and energy sectors. Even with automation and modernization, Gary Works still employs over 3,000 people and remains a critical part of the regional economy.

Fairfield Works in Alabama

U.S. Steel’s Fairfield Works in Fairfield, Alabama, just outside Birmingham, has been operating since 1907. This facility is unique because it’s one of the few remaining integrated mills in the South that still uses a blast furnace. It processes iron ore, coke, and limestone into raw steel, then rolls it into sheets and coils. The plant supplies steel for appliances, tubing, and industrial equipment. Its location near major highways and rail lines makes it ideal for distributing products across the Southeast. In recent years, Fairfield Works has invested over $500 million in upgrades to reduce emissions and improve efficiency, including new continuous casting and coating lines.

Mon Valley Works in Pennsylvania

Mon Valley Works is a complex of three facilities-Irvin Plant, Edgar Thomson Plant, and Clairton Coke Works-located along the Monongahela River near Pittsburgh. This is where U.S. Steel’s legacy began. Edgar Thomson Plant, opened in 1875, was Andrew Carnegie’s first steel mill and is still in operation today. It produces slab steel for flat products. Clairton Coke Works, the largest coke production facility in the U.S., turns coal into coke-the fuel that powers blast furnaces. The Irvin Plant does finishing work, rolling steel into sheets and plates. Together, these sites produce about 4 million tons of steel annually. Despite challenges from cheaper imports and automation, U.S. Steel continues to invest here because of its deep-rooted infrastructure and skilled workforce.

Great Lakes Works in Michigan

Great Lakes Works, located in Ecorse, Michigan, near Detroit, is a finishing mill that doesn’t produce raw steel but transforms incoming slabs into finished products. It’s one of the most automated steel plants in the country, using robotics and AI-driven quality control. The plant specializes in cold-rolled and galvanized steel used in appliances, HVAC systems, and automotive parts. It gets its raw slabs shipped by rail from Gary Works and other U.S. Steel mills. Great Lakes Works employs around 1,200 people and has been upgraded multiple times since its founding in 1947. Its proximity to the auto industry makes it a key supplier for the Detroit Three automakers.

Minneapolis Steel Plant in Minnesota

U.S. Steel’s plant in Minneapolis, Minnesota, is not a full-scale integrated mill. Instead, it’s a specialty facility focused on producing tubular products and steel pipes for the oil, gas, and water industries. It uses seamless tube technology and processes steel billets shipped in from other U.S. Steel locations. The plant has been in operation since the 1950s and serves energy companies across the Midwest and Rocky Mountain states. Its location near major pipeline corridors and rail hubs makes it a strategic asset for energy infrastructure projects.

Marinette Plant in Wisconsin

The Marinette, Wisconsin, plant is another finishing facility that doesn’t produce raw steel. It specializes in producing high-strength, cold-rolled steel for heavy-duty applications like construction equipment and mining machinery. The plant receives slabs from Gary Works and processes them using advanced rolling and heat-treatment systems. It’s one of the few U.S. Steel sites that still produces steel plate for shipbuilding and offshore drilling platforms. With over 600 employees, it’s a major employer in the region and has seen consistent investment since its acquisition by U.S. Steel in 2003.

Why These Locations? The Logic Behind the Map

U.S. Steel doesn’t pick plant locations randomly. Each site was chosen based on three key factors: access to raw materials, transportation networks, and customer demand. The Great Lakes region, for example, was ideal because iron ore from Minnesota could be shipped cheaply by bulk freighter. Coal from Appalachia could be brought in by rail. Water from the lakes cooled equipment and helped with processing. Today, rail and highway access still matter just as much. Mills near Detroit supply automakers. Plants in Arkansas and Alabama serve construction and appliance manufacturers. Even with global supply chains, U.S. Steel keeps production close to its customers to cut shipping costs and delivery times.

What’s Changing? Automation, Sustainability, and New Tech

U.S. Steel is shifting away from older, coal-heavy methods. Big River Steel’s electric arc furnace model is the future. The company is also testing hydrogen-based steelmaking at Gary Works, a process that could cut carbon emissions by up to 90%. Automation is reducing the need for manual labor-robots now handle much of the heavy lifting, inspection, and packaging. But that doesn’t mean jobs are disappearing. Instead, the workforce is shifting toward technicians, engineers, and data analysts who manage these new systems. The goal isn’t just to make steel-it’s to make it cleaner, faster, and smarter.

How These Plants Serve the U.S. Economy

U.S. Steel’s plants don’t just make metal-they enable entire industries. The steel from Gary Works goes into the steel beams of new hospitals. The sheets from Fairfield Works end up in your refrigerator. The pipes from Minneapolis carry natural gas across the country. The auto parts from Great Lakes Works are in your car. Even small businesses rely on U.S. Steel’s products: a local farm might use steel fencing made from coils rolled in Marinette. In 2024, U.S. Steel supplied over 20% of the domestic flat-rolled steel market and supported more than 50,000 indirect jobs across the country.

What’s Next for U.S. Steel’s Facilities?

U.S. Steel is planning more upgrades in the next five years. Gary Works will get a new hydrogen injection system. Big River Steel is expanding its capacity to meet rising demand for electric vehicle steel. The company is also exploring partnerships with renewable energy providers to power mills with wind and solar. While some older plants may eventually close, the focus is on modernizing the ones that remain. The U.S. government’s Infrastructure Investment and Jobs Act is helping fund these transitions, with over $1 billion in federal grants allocated to clean steel projects since 2022.

Are all U.S. Steel plants still operating?

Yes, all seven major U.S. Steel facilities are currently operational as of 2025. This includes Gary Works, Big River Steel, Fairfield Works, Mon Valley Works, Great Lakes Works, the Minneapolis tubular plant, and the Marinette finishing mill. Some older units within these complexes have been retired, but the core production sites remain active and are being upgraded.

Which U.S. Steel plant is the largest?

The Gary Works in Indiana is the largest U.S. Steel facility, producing over 7 million tons of steel annually. It’s also one of the biggest integrated steel mills in the Western Hemisphere, with six blast furnaces and extensive rolling and finishing lines.

Is U.S. Steel still using coal in its plants?

Yes, but only at its integrated mills like Gary Works, Fairfield Works, and Mon Valley Works. These plants still use coal to make coke, which fuels blast furnaces. However, Big River Steel in Arkansas uses no coal-it runs on electricity and scrap metal. U.S. Steel is testing hydrogen-based steelmaking at Gary Works to phase out coal over the next decade.

Can I visit a U.S. Steel plant?

Public tours are rare, but some facilities, like Gary Works and Big River Steel, offer limited educational visits for schools and industry groups. You’ll need to contact U.S. Steel’s community relations department in advance. Safety protocols are strict due to high temperatures, heavy machinery, and hazardous materials.

How many employees work at U.S. Steel plants?

U.S. Steel directly employs about 18,000 people across its U.S. facilities as of 2025. Most of these workers are at Gary Works, Mon Valley Works, and Fairfield Works. The rest are spread across finishing plants and specialty facilities. When you include suppliers, logistics, and maintenance contractors, the total number of jobs supported exceeds 50,000.

Final Thoughts: Steel Still Matters

Steel isn’t just a commodity-it’s the skeleton of modern America. From the bridges you drive over to the wind turbines generating clean energy, U.S. Steel’s plants are still essential. Their locations aren’t accidents of history; they’re strategic choices that still make sense today. Whether it’s the electric arc furnace in Arkansas or the century-old blast furnace in Pennsylvania, these facilities are adapting, not fading. The future of American manufacturing still runs on steel-and it’s still being made right here at home.