5 μm: What It Means in Manufacturing and Why It Matters

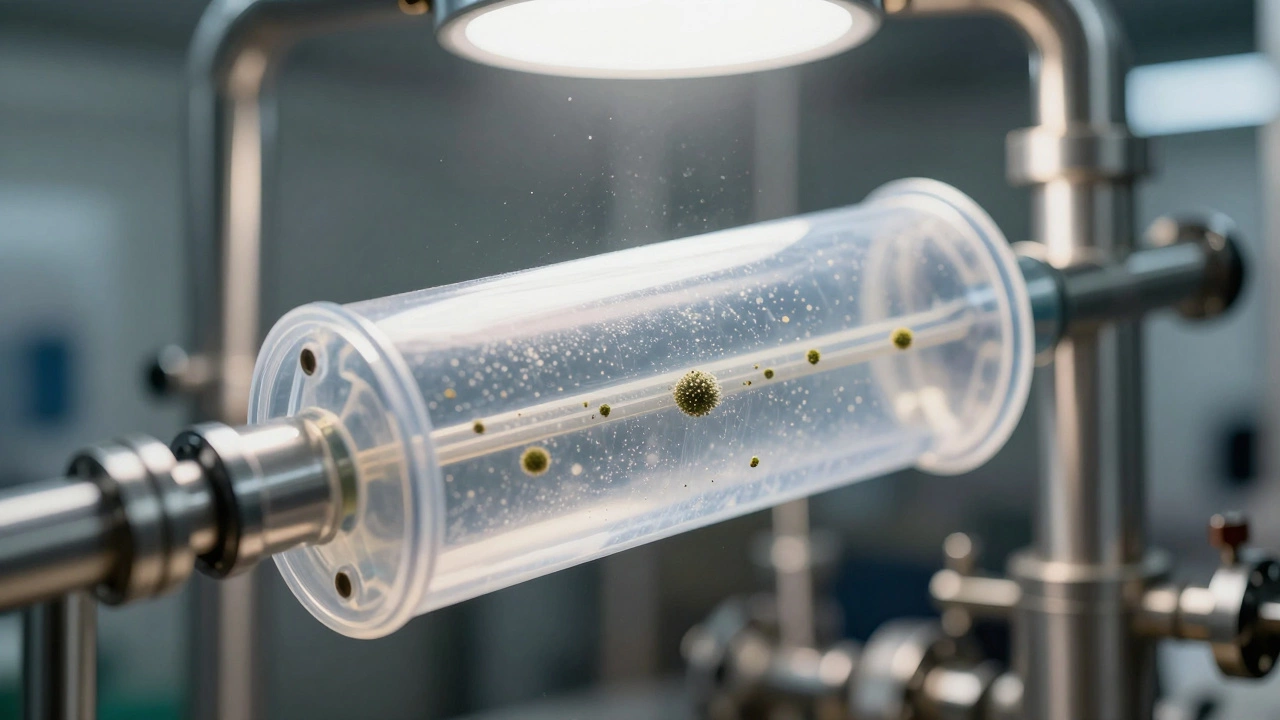

When you hear 5 μm, a unit of measurement equal to five micrometers, or one-thousandth of a millimeter. Also known as five microns, it's the size of particles that can slip past basic filters and still affect air quality, machinery wear, and product purity. In HVAC and industrial manufacturing, 5 μm isn’t just a number—it’s a turning point. Particles this small can carry dust, mold, bacteria, and even chemical vapors through ventilation systems, reducing efficiency and risking health. That’s why filters rated for 5 μm or smaller are the baseline for cleanrooms, pharmaceutical plants, and modern commercial HVAC setups across India.

Think of it this way: a human hair is about 70 μm wide. A 5 μm particle is fourteen times smaller. It’s invisible to the naked eye, but in a factory where precision matters—like electronics assembly or food processing—it’s a big deal. If your air filter can’t catch 5 μm particles, you’re letting in contaminants that can ruin sensitive components, trigger allergic reactions, or spoil batches. That’s why leading Indian manufacturers of HVAC equipment now design systems with multi-stage filtration, targeting 5 μm and below. It’s not marketing jargon; it’s engineering necessity. And it’s tied directly to India’s push for better indoor air standards in factories, hospitals, and data centers.

Related to this are filtration efficiency, how well a filter captures particles of specific sizes, and HEPA standards, a global benchmark for air purification. Many high-end HVAC units in India now meet or exceed HEPA H13 ratings, which guarantee 99.95% capture of 0.3 μm particles—far tighter than 5 μm. But even if you’re not using HEPA, knowing that 5 μm is the threshold where most industrial filters start delivering real value helps you choose the right system. It’s the sweet spot between cost and performance. Too loose, and you get dust buildup. Too tight, and airflow drops, straining your motors. Manufacturers who understand this balance build systems that last longer, use less energy, and keep environments cleaner.

Across India’s growing manufacturing base—from textile mills in Tamil Nadu to electronics plants in Karnataka—controlling airborne particles at the 5 μm level is becoming non-negotiable. It’s why small factories are upgrading from basic mesh filters to pleated synthetic media. Why food processing units now monitor air quality daily. Why even startups in Gujarat and Punjab are asking for 5 μm-rated HVAC systems before they sign leases. This isn’t about luxury. It’s about compliance, safety, and protecting your investment. The posts below show you exactly how this plays out in real factories, what standards Indian manufacturers are following, and how you can spot a system that actually delivers on its 5 μm claims—without overpaying for features you don’t need.