5 μm Filtration Efficiency Calculator

Enter filter size and contaminant size to see capture efficiency and contamination risk

When you see 5 μm written on a food processing machine spec sheet, filter label, or quality control report, it’s not just a number-it’s a line in the sand between safe food and contaminated food. That tiny unit-five micrometers-is the threshold that separates harmless particles from dangerous ones in everything from powdered spices to bottled juices. If you work in food production, packaging, or even quality assurance, understanding what 5 μm means isn’t optional. It’s the difference between passing an inspection and facing a recall.

What Exactly Is a Micrometer?

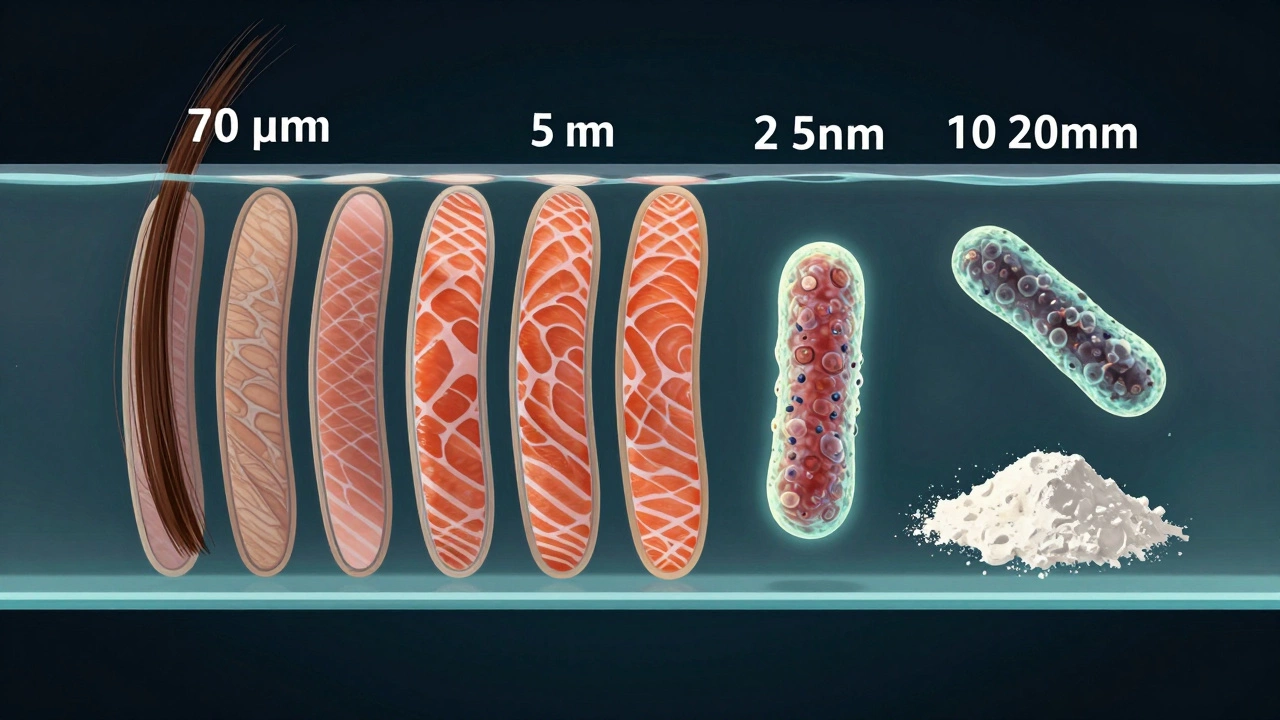

A micrometer, written as μm (or micron), is one-millionth of a meter. To picture it: a human hair is about 70 μm thick. So 5 μm is like cutting that hair into 14 equal slices and taking just one. In food processing, this scale matters because many contaminants-bacteria, mold spores, metal shavings, dust, even insect parts-are measured in micrometers. A single Salmonella cell is roughly 2-5 μm long. A grain of fine flour might be 10-20 μm. So when a filter is rated at 5 μm, it’s designed to catch particles that are 5 μm or larger.Why 5 μm Is the Gold Standard in Food Filtration

In food processing, filtration isn’t just about clarity-it’s about safety. Liquids like milk, fruit juice, syrup, and broth often pass through multi-stage filters before bottling. The final stage? Often a 5 μm filter. Why not 1 μm? Because finer filters clog faster, increase pressure, and cost more. Why not 10 μm? Because that lets through too many risks. Five micrometers strikes a balance: it removes the vast majority of visible and invisible threats without crippling efficiency.Take juice production. If a 10 μm filter is used, it might let through fragments of mold, insect parts, or even tiny pieces of packaging material. But a 5 μm filter catches those. In powdered products like protein mixes or infant formula, 5 μm is the benchmark for ensuring no foreign particulates slip into the final blend. The FDA and Codex Alimentarius don’t always specify 5 μm outright-but they require that final products be free of harmful particulates. In practice, 5 μm filtration is the industry’s way of meeting that requirement reliably.

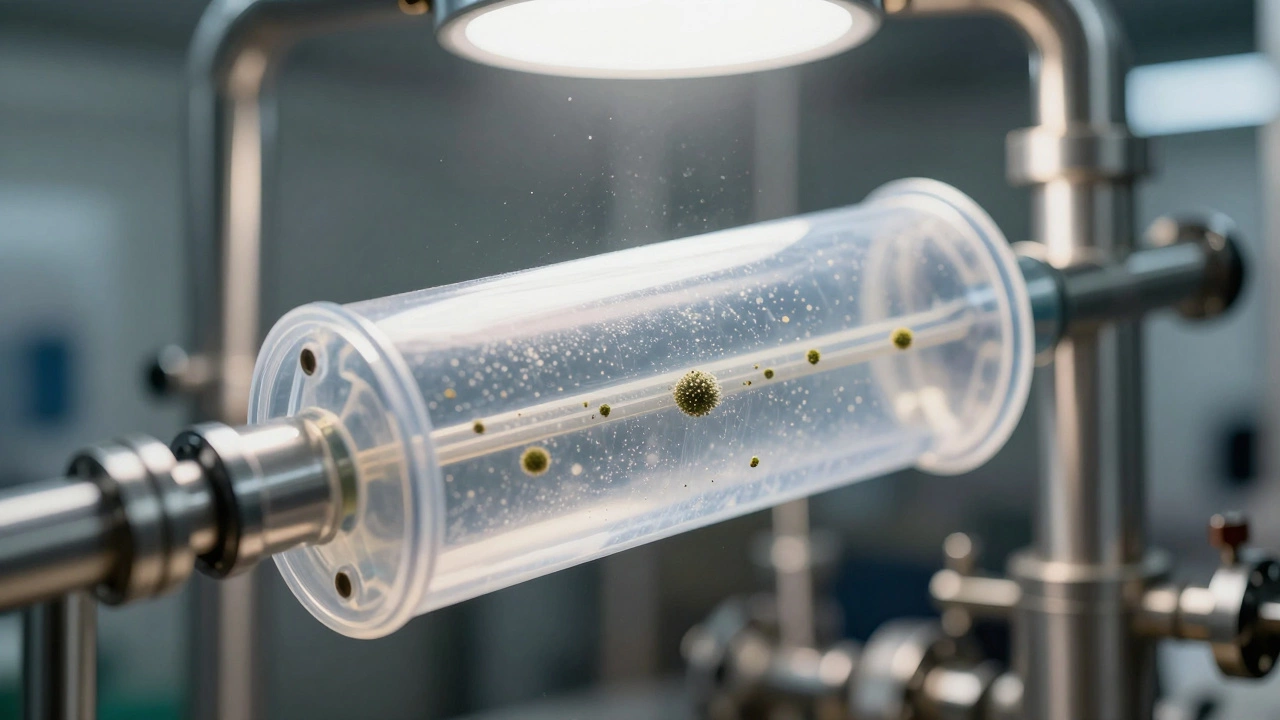

How 5 μm Filters Work in Real Food Lines

You won’t see a single filter labeled "5 μm" and think it’s magic. It’s part of a system. In a typical juice plant, liquid flows through several stages:- Pre-filtration at 50-100 μm to remove large debris like pulp chunks or leaves.

- Intermediate filtration at 10-20 μm to catch finer particles.

- Final 5 μm membrane filter to trap bacteria, yeast, and micro-particles.

This isn’t just about cleaning-it’s about protecting the product’s shelf life. Yeast and mold spores are often 5-10 μm. If they get through, they can grow in sealed bottles, causing swelling, off-flavors, or even explosions. A 5 μm filter stops them before they start.

For dry ingredients, like powdered milk or cocoa, 5 μm is measured in terms of particle size distribution. Sieves and air classifiers are used to ensure no particle exceeds 5 μm in diameter. Why? Because finer particles can become airborne during handling, posing inhalation risks to workers and contamination risks to other products. In facilities that handle allergens like peanuts or soy, even a single 5 μm particle of residue can trigger reactions in sensitive consumers.

What Happens If You Use a 10 μm Filter Instead?

Some small processors try to cut costs by skipping to 10 μm filters. It seems harmless-after all, the liquid looks clear. But here’s what you’re risking:- Up to 40% more yeast and mold spores passing through.

- Higher chance of microbial growth in shelf-stable products.

- Increased risk of recalls due to foreign material complaints.

- Fines from regulators during unannounced inspections.

A 2023 audit by the Global Food Safety Initiative found that 68% of recalls linked to particulate contamination involved products that used filtration above 5 μm. The average cost of one recall? $1.2 million-not including brand damage.

How to Verify Your 5 μm Filters Are Working

Buying a filter labeled "5 μm" doesn’t guarantee it’s performing. Filters degrade. They get clogged. They’re installed wrong. Here’s how to check:- Use a particle counter: Place a portable laser particle counter after the filter. It will count particles larger than 5 μm in real time. If you see more than 10 particles per mL in a clear liquid, your filter is failing.

- Check pressure drop: A sudden spike in pressure across the filter means it’s clogged and may be bypassing. Replace it.

- Perform a dye test: Inject a harmless, visible dye (like food-grade red dye) before the filter. If any color appears downstream, the filter has a tear or leak.

- Keep logs: Record filter changes, pressure readings, and particle counts daily. Regulators ask for this during inspections.

One dairy plant in Wisconsin reduced microbial contamination by 92% after switching to daily particle counting instead of just changing filters on a schedule.

5 μm and Allergen Control

If your facility handles multiple products-say, peanut butter one day, almond butter the next-cross-contamination is a nightmare. Even a speck of peanut protein, measuring just 2-5 μm, can trigger anaphylaxis. That’s why many allergen-sensitive facilities require 5 μm filtration on air intakes, vacuum systems, and cleaning water lines. Some even use 5 μm HEPA filters in ventilation to capture airborne allergens. The CDC estimates 15 million Americans have food allergies. A single 5 μm particle can be enough to harm one of them.

What About 1 μm or 0.2 μm Filters?

Some processes use tighter filters. Sterile filling lines for infant formula often use 0.2 μm filters to remove all bacteria, including endospores. But these are expensive, slow, and require sterilization between uses. They’re overkill for most food products. You don’t need to sterilize orange juice-you just need to remove the stuff that makes people sick. That’s where 5 μm shines: it’s the sweet spot between safety, cost, and practicality.Common Misconceptions About 5 μm

- "5 μm means all particles smaller than that are safe." False. Viruses are 0.02-0.3 μm. They pass through 5 μm filters. But viruses don’t cause particulate contamination-they’re removed by pasteurization or UV treatment. Filtration isn’t your only defense.

- "Clear liquid means it’s clean." Not true. Many harmful particles are invisible to the eye. Only testing can confirm.

- "We’ve never had a problem, so we don’t need it." That’s how recalls start. Compliance isn’t about luck-it’s about control.

What Should You Do Next?

If you’re in food processing:- Check your current filtration specs. Are you using 5 μm as your final barrier?

- Ask your filter supplier for certification that their media meets ISO 16889 or ASTM F838 standards.

- Start logging particle counts weekly-even if you’re not required to.

- Train your team: every operator should know what 5 μm means and why it matters.

It’s not about being perfect. It’s about being predictable. When regulators come in, they don’t want to hear "We’ve always done it this way." They want to see data, logs, and proof that you control your process. 5 μm isn’t just a number. It’s your evidence that you take safety seriously.

Is 5 μm the same as 5 microns?

Yes. "Micron" is just an older, informal term for micrometer (μm). Both mean one-millionth of a meter. In food processing, the terms are used interchangeably.

Can a 5 μm filter remove bacteria?

Most common bacteria, like E. coli and Salmonella, are between 1 and 5 μm in size. A properly functioning 5 μm filter will catch the majority of them. But some smaller bacteria or spores may pass through. That’s why filtration is always paired with heat treatment or chemical disinfection in food processing.

Do all food products need 5 μm filtration?

Not every product requires it, but most liquid and powdered foods do. Juices, dairy, syrups, powdered spices, infant formula, and protein blends almost always use 5 μm as the final filtration step. Dry, solid foods like whole nuts or frozen vegetables rely more on visual inspection and metal detection.

How often should 5 μm filters be changed?

It depends on usage. In high-volume juice lines, filters may need replacing every 8-12 hours. In low-volume spice processing, once a week might be enough. The best practice is to change them based on pressure drop or particle count-not just time. A clogged filter can rupture or bypass, letting contaminants through.

What happens if a 5 μm filter fails during production?

Any product produced after a filter failure must be quarantined and tested. If contamination is confirmed, the batch is destroyed or reprocessed. Many facilities install automatic shut-off valves that stop production if pressure drops too low-indicating a ruptured or bypassed filter. This prevents contaminated product from reaching customers.