Food Particle Size: What It Means for Processing, Safety, and Profit

When you hear food particle size, the physical dimension of solid fragments in food products, from flour to powdered spices. Also known as particle size distribution, it determines how food mixes, cooks, preserves, and even tastes. It’s not just about how fine or coarse something looks—it’s a core factor in whether your product works, sells, or gets rejected by regulators.

Small particles dissolve faster, which matters in instant drinks or baby food. Large particles can create uneven texture, risk choking, or cause machinery jams. In spice grinding, particle size affects flavor release—too coarse, and you lose potency; too fine, and you risk clumping or oxidation. The same logic applies to powdered milk, protein blends, and even frozen meals. If your particle size isn’t controlled, your batch might fail quality checks, spoil faster, or get returned by customers.

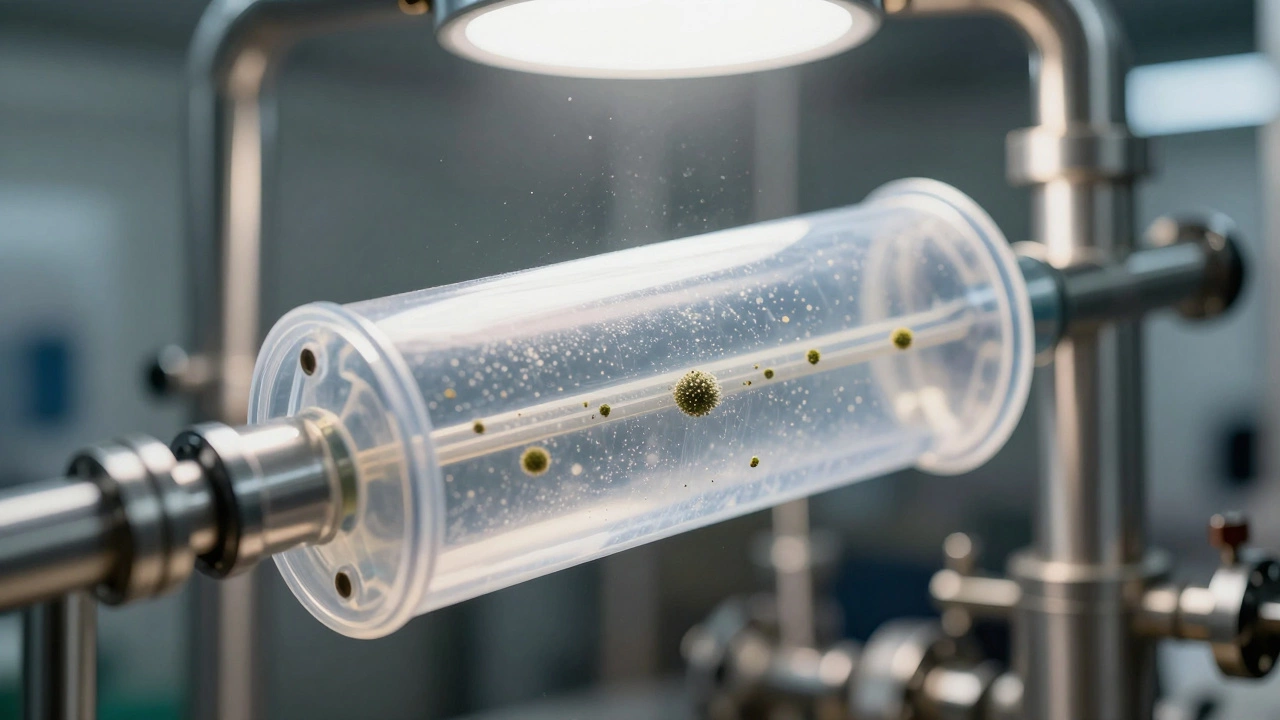

It’s not just about the food itself—it’s about the machines and methods used. food processing, the series of steps that turn raw ingredients into packaged goods relies on particle size at every stage: milling, blending, drying, and packaging. If you’re using a hammer mill, jet mill, or sieve shaker, you’re managing particle size. And if you’re following a food processing sequence, the ordered steps from raw material receipt to final packaging, particle size control is often a non-negotiable checkpoint before sterilization or packaging.

Why does this matter to manufacturers? Because particle size directly impacts yield, energy use, and shelf life. A finer grind might mean more product per batch—but it also uses more power and can trigger dust explosions. A coarser grind saves energy but might need extra stabilizers to prevent separation. In India’s growing food processing sector, where margins are tight and competition is rising, getting particle size right is one of the cheapest ways to boost quality and cut waste.

You’ll find this topic popping up in posts about food processing, high-margin food products, and how small factories cut costs. Whether it’s grinding turmeric in a rural unit or blending infant formula in a certified plant, particle size isn’t a technical footnote—it’s a profit lever. The right size means less waste, fewer complaints, and faster production. The wrong size? Lost batches, recalls, or worse.

Below, you’ll find real examples from Indian manufacturers who nailed their particle size control—and those who didn’t. You’ll see how it ties into machinery choices, regulatory standards, and the bottom line. No theory. No fluff. Just what works on the factory floor.