When you think of American manufacturing, you might picture factories in the Rust Belt or tech plants in Silicon Valley. But the city that actually produces the most manufactured goods in the U.S. isn’t Detroit, Chicago, or even Los Angeles. It’s Los Angeles - and it’s not even close.

Los Angeles Leads in Manufacturing Output

In 2024, Los Angeles County shipped over $112 billion in manufactured goods, according to the U.S. Census Bureau’s Annual Survey of Manufacturers. That’s more than the entire state of Ohio and nearly double what Chicago produces. The city isn’t just making cars or steel - it’s building everything from aerospace parts and medical devices to fashion apparel and food packaging.

The secret? Diversity. Unlike older manufacturing hubs that relied on one or two industries, Los Angeles has 13 distinct manufacturing sectors each generating over $1 billion in annual output. Electronics, apparel, and food processing make up the biggest chunks, but aerospace and medical device manufacturing are growing fast thanks to defense contracts and federal health funding.

Why Los Angeles? It’s Not Just Factories

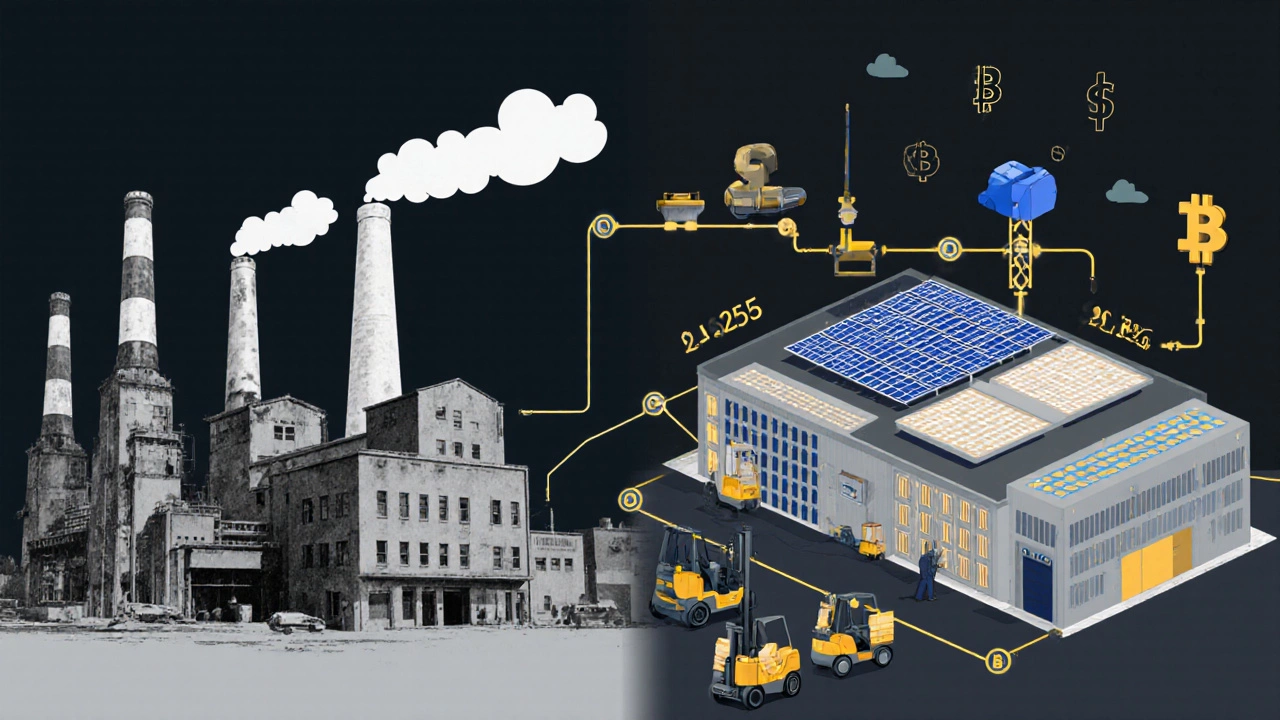

Most people assume manufacturing means big smokestacks and assembly lines. But today’s manufacturing is smarter, smaller, and more distributed. Los Angeles thrives because it’s built for flexibility. A single warehouse in Vernon might house 20 different small manufacturers - one making drone parts, another printing custom labels, a third assembling medical implants.

The city’s port is the busiest in the Western Hemisphere, bringing in raw materials from Asia and shipping out finished goods worldwide. Its labor force includes skilled welders, CNC operators, and engineers - many trained through state-funded programs like California’s Manufacturing Extension Partnership and federal Manufacturing USA institutes. These aren’t just training programs; they’re pipelines that connect local workers directly to employers.

Government Schemes Fuel the Growth

The federal government has poured over $4 billion into manufacturing incentives since 2021 through the CHIPS and Science Act and the Inflation Reduction Act. Los Angeles captured more than $700 million of that - the highest of any metro area.

Companies like SpaceX, Medtronic, and Apple’s supplier network got tax credits for expanding local production. Small manufacturers got grants to upgrade to automation. The state of California added its own layer: the Manufacturing Jobs Tax Credit gives businesses up to $20,000 per new hire for five years. Over 12,000 manufacturing jobs were created in LA County alone between 2022 and 2024 because of these programs.

It’s not just money - it’s infrastructure. The federal government funded a new advanced manufacturing hub in the Port of Los Angeles, where startups can test robotics and AI-driven production lines without buying expensive equipment. That’s how a 3-person team in Compton can now make custom prosthetics at scale - something that would’ve been impossible five years ago.

Other Top Contenders - And Why They Fall Short

Chicago still ranks high, with $58 billion in output. It’s strong in machinery, food processing, and metal fabrication. But it’s losing ground. Between 2018 and 2024, Chicago lost nearly 15% of its manufacturing jobs as companies moved production closer to ports or to states with better incentives.

Detroit? Its automotive output has dipped below $40 billion after years of decline. While electric vehicle factories are rising, they’re not yet enough to replace the old internal combustion engine supply chains.

Houston leads in chemical manufacturing, but that’s just one sector. Atlanta has a booming aerospace cluster. But neither comes close to LA’s mix of scale, diversity, and government-backed support.

What’s Next for U.S. Manufacturing?

The next wave of manufacturing won’t be about size - it’ll be about speed, customization, and resilience. Los Angeles is already ahead. Companies there are using AI to predict demand, 3D printing to reduce inventory, and blockchain to track parts from raw material to finished product.

Other cities are trying to catch up. Texas is offering big tax breaks. Ohio is investing in worker training. But LA has something others can’t copy easily: decades of built-up supply chains, a multicultural workforce fluent in global markets, and a government ecosystem that actually delivers on promises.

If you’re looking to start a manufacturing business in the U.S., don’t just look for cheap land. Look for places where the government is already helping manufacturers succeed. LA isn’t just the biggest - it’s the most connected, the most supported, and the most ready for what comes next.

How Manufacturing Jobs Are Changing

Manufacturing jobs aren’t disappearing - they’re evolving. In 1990, a factory worker might’ve spent their day operating a single machine. Today, they’re managing robots, reading digital dashboards, and troubleshooting software glitches.

Wages are up, too. The average manufacturing worker in Los Angeles County earns $68,000 a year - 22% higher than the national average for all jobs. And 63% of those jobs don’t require a four-year degree. Community colleges like Los Angeles Trade-Technical College offer six-month certifications in CNC machining, robotics maintenance, and quality control - all with job placement rates above 85%.

It’s a myth that manufacturing is dead. It’s just not the same as it was. The new factories don’t smell like oil. They hum with quiet efficiency. And they’re paying better than ever.

Why This Matters for the Future

Manufacturing isn’t just about making things. It’s about keeping supply chains secure, creating middle-class jobs, and driving innovation. When the U.S. needed ventilators during the pandemic, the fastest production came from LA-based medical device makers who’d already been working with government partners.

When electric vehicle batteries needed new materials, it was LA’s chemical labs that helped develop alternatives to Chinese-sourced lithium. When the Pentagon needed drones, it turned to startups in the city’s tech-manufacturing corridor.

Los Angeles proves that manufacturing can thrive in a modern economy - if you invest in people, technology, and smart policy. Other cities can follow. But right now, none have done it better.

What city in the U.S. has the most manufacturing jobs?

Los Angeles County has the most manufacturing jobs in the U.S., with over 420,000 workers employed in the sector as of 2024. That’s more than Chicago, Detroit, and Houston combined. The jobs span apparel, electronics, aerospace, food processing, and medical devices - not just traditional heavy industry.

Is manufacturing coming back to the U.S.?

Yes - but not the way it used to be. U.S. manufacturing output hit a record $2.4 trillion in 2024, up 11% since 2020. The comeback is driven by government incentives, supply chain concerns, and automation. Instead of mass-producing cheap goods, companies are making high-value, customized products closer to home. Los Angeles, Cincinnati, and Austin are leading this shift.

What government programs support U.S. manufacturing?

The main federal programs are the CHIPS and Science Act (funding semiconductor production), the Inflation Reduction Act (tax credits for clean energy manufacturing), and Manufacturing USA (public-private R&D hubs). States like California, Ohio, and Texas add their own incentives - including tax credits, training grants, and low-interest loans for equipment upgrades.

Does manufacturing still pay well?

Absolutely. The average manufacturing wage in the U.S. is $28.50 per hour - higher than the average for all private-sector jobs. In top manufacturing cities like Los Angeles, wages reach $32-$35 per hour. Many roles require only a two-year technical degree or certification, making manufacturing one of the best paths to a middle-class income without a four-year college.

Why isn’t Detroit the top manufacturing city anymore?

Detroit’s economy was built on one industry: cars. When global competition and automation hit, the city struggled to diversify. While EV production is growing, the overall manufacturing output in the Detroit metro area has dropped by 18% since 2015. Los Angeles, by contrast, has 13 major manufacturing sectors - so if one declines, others keep the economy strong.

What to Watch in 2026

Look for three trends in the next year: First, more factories will use AI to predict maintenance needs before machines break. Second, the federal government will expand its “Made in America” procurement rules - meaning more contracts will go to U.S.-based manufacturers. Third, smaller cities like Nashville and Salt Lake City will start attracting manufacturing because of lower costs and skilled labor pipelines.

But for now, Los Angeles remains the undisputed leader. It’s not just the numbers - it’s the ecosystem. The factories, the workers, the training programs, the port, the federal dollars - they all work together. That’s what makes it unstoppable.